- |

- Products

- |

- Oil Temperature Control Units

- |

- TT-410 X

Metric

High performance unit with wide temperature range: -20°C up to +240°CTT-410 X

Reactors from 50 up to 150 litres

Summary

- Maximum temperature 240°C

- Medium oil

- Heating capacity 48 kW

- cooling capacity

150 kW @ 230°C indirect

175 kW @ 80°C direct - Cooling system indirect

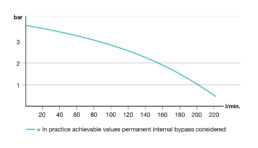

- Pump capacity 260 l/min; max. 4.0 bar

Functions

- Self-optimizing temperature controller with temperature display

1/10°C – steps - Display in °C or °F and l/min or gal/min

- Digital flow display and monitoring

- Automatic temperature control

- Switchover for temperature control at the consumer

- Heating switchable in stages

- Heaters with cascade connection

- Pressure indication: pump, compressed air unit, compressed air mains

- With pressure regulation

Construction

- High-performance centrifugal pump

- Hot oil circuit with bypass, which ensures the internal oil circulation when the valves are closed

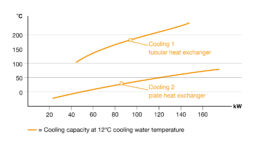

- With two cooling circuits:

circuit 1: +80°C to +240°C

circuit 2: -20°C to +80°C - Limescale free heat exchanger

- No cracking of the oil thanks to special heating construction

- All parts in contact with water are made of stainless steel or bronze

- Unit on adjustable feet

Safety features

- Level control for dry run protection

- Expansion vessel with safety shut-off in case of overflow

- Electronic temperature limitation and monitoring in the controller

- Mechanical safety thermostats

- Visual and acoustic fault indications

- Integrated circuit breakers

- Main switch, transformer and motor protection switch

Product informationsTT-410 X

| Product | TT-410 X | ||||

|---|---|---|---|---|---|

| Temperature range | °C | 240 | |||

| Heat transfer medium | oil | ||||

| Filling amount | l | 75 | |||

| Expansion volume | l | 75 | |||

| Heating capacity | kW | 48 | |||

| Cooling system | indirect | ||||

| Tubular heat exchanger | kW | 150 | |||

| Plate heat exchanger | kW | 175 | |||

| At flow temperature | °C | 230 I 80 | |||

| Pump | |||||

| Motor | kW | 4 | |||

| Pump system see diagram | |||||

| Typ Z: axial face sealed 100 l/min; max. 5.5 bar | |||||

| Typ A: magnetic drive 100 l/min; max. 5.5 bar | |||||

| Typ X: 260 l/min; max. 4.0 bar | ⚫ | ||||

| Typ Y: 200-500 l/min; max. 4.0 bar | |||||

| Suction capacity vakuum | mWS | - | |||

| Controller | MP-888 | ||||

| Measurement sensor | Pt-100 | ||||

| Connections | |||||

| Medium | flange DN32 / PN 16 | ||||

| Cooling water outlet | 1 1/2" BS | ||||

| Cooling water inlet | |||||

| Water-glycol | 1 1/2" BS | ||||

| Compressed air min. | bar | 5 | |||

| Dimensions incl. castors, LxWxH | mm | 1710x790x1540 | |||

| Weight empty approx. | kg | 590 | |||

| Colour | silvergrey RAL 7001 | ||||

| Functions | ● standard/ ○ optional / - not possible | ||||

| Flow control | ⚫ | ||||

| Leakstopper device | - | ||||

| Mould drain | - | ||||

| Temperature regulation at the consumer | ⚫ | ||||

| Interface controller | ◯ | ||||

| Level control | ⚫ | ||||

| Visual fault indications | ⚫ | ||||

| Acoustic warning | ⚫ | ||||

| Pressure regulation | ⚫ | ||||

| Double circuit version | - | ||||

Imperial

High performance unit with wide temperature range: -4°F up to 464°FTT-410 X

Reactors from 13.2 up to 39.6 gallons

Summary

- Maximum temperature 464°F

- Medium oil

- Heating capacity 163‘783 BTU/hr

- cooling capacity

150 kW @ 446°F indirect

175 kW @ 176°F direct - Cooling system indirect

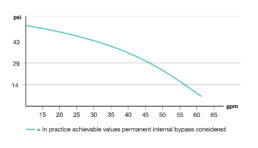

- Pump capacity 132 gpm; max. 58 psi

Functions

- Self-optimizing temperature controller with temperature display

1/10°F – steps - Display in °C or °F and l/min or gal/min

- Digital flow display and monitoring

- Automatic temperature control

- Switchover for temperature control at the consumer

- Heating switchable in stages

- Heaters with cascade connection

- Pressure indication: pump, compressed air unit, compressed air mains

- With pressure regulation

Construction

- High-performance centrifugal pump

- Hot oil circuit with bypass, which ensures the internal oil circulation when the valves are closed

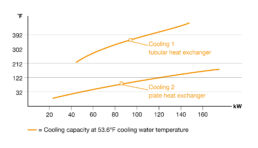

- With two cooling circuits:

circuit 1: 176°F to 464°F

circuit 2: -4°F to 176°F - Limescale free heat exchanger

- No cracking of the oil thanks to special heating construction

- All parts in contact with water are made of stainless steel or bronze

- Unit on adjustable feet

Safety features

- Level control for dry run protection

- Expansion vessel with safety shut-off in case of overflow

- Electronic temperature limitation and monitoring in the controller

- Mechanical safety thermostats

- Visual and acoustic fault indications

- Integrated circuit breakers

- Main switch, transformer and motor protection switch

Product informationsTT-410 X

| Product | TT-410 X | ||||

|---|---|---|---|---|---|

| Temperature range | °F | 464 | |||

| Heat transfer medium | oil | ||||

| Filling amount | US gal | 19.8 | |||

| Expansion volume | US gal | 19.8 | |||

| Heating capacity | BTU/hr | 163'783 | |||

| Cooling system | indirect | ||||

| Tubular heat exchanger | kW | 150 | |||

| Plate heat exchanger | kW | 175 | |||

| At flow temperature | °F | 446 I 176 | |||

| Pump | |||||

| Motor | HP | 5.4 | |||

| Pump system see diagram | |||||

| Typ Z: axial face sealed 26.4 gpm; max. 80 psi | |||||

| Typ A: magnetic drive 26.4 gpm; max. 80 psi | |||||

| Typ X: 69 gpm; max. 58 psi | ⚫ | ||||

| Typ Y: 53-132 gpm; max. 58 psi | |||||

| Suction capacity vakuum | inHg | - | |||

| Controller | MP-888 | ||||

| Measurement sensor | Pt-100 | ||||

| Connections | |||||

| Medium | flange DN32 / PN 16 | ||||

| Cooling water outlet | 1 1/2" NPT | ||||

| Cooling water inlet | |||||

| Water-glycol | 1 1/2" NPT | ||||

| Compressed air min. | psi | 73 | |||

| Dimensions incl. castors, LxWxH | inch | 67.3x31.1x60.6 | |||

| Weight empty approx. | lbs | 1301 | |||

| Colour | silvergrey RAL 7001 | ||||

| Functions | ● standard/ ○ optional / - not possible | ||||

| Flow control | ⚫ | ||||

| Leakstopper device | - | ||||

| Mould drain | - | ||||

| Temperature regulation at the consumer | ⚫ | ||||

| Interface controller | ◯ | ||||

| Level control | ⚫ | ||||

| Visual fault indications | ⚫ | ||||

| Acoustic warning | ⚫ | ||||

| Pressure regulation | ⚫ | ||||

| Double circuit version | - | ||||