- |

- Products

- |

- Oil Temperature Control Units

- |

- TT-390

Metric

Oil temperature control unit - also available as 2-circuit deviceTT-390

Moulds, rollers, plates

Eckdaten

- Maximum temperature 360°C

- Medium oil

- Heating capacity 16 kW I 24 kW

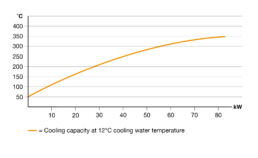

- Cooling capacity 90 kW @ 360°C

- Cooling system indirect

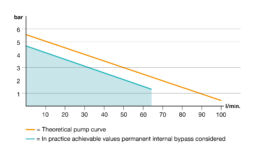

- Pump capacity with axial face seal 100 l/min; max. 5.5 bar

- With magnetic drive 100 l/min; max. 5.5 bar

Functions

- Self-optimizing temperature controller with temperature display

1/10°C – steps - Display in °C or °F and l/min or gal/min

- Digital flow display and monitoring

- Automatic temperature control

- Switchover for temperature control on the mould

- Heating switchable in stages

- Heaters with cascade connection (only 24 kW)

- Pressure display

- Automatic mould drainage

- Leakstopper device – operation in pressure and vacuum mode possible

Construction

- High temperature pump with mechanical seal or magnetic coupling

- Hot oil circuit with bypass, which ensures the internal oil circulation when the valves are closed

- Limescale free heat exchanger

- No cracking of the oil thanks to special heating construction

- Expansion tank with drip pan

- Unit on castors

Safety features

- Level control for dry run protection

- Expansion vessel with safety shut-off in case of overflow

- Electronic temperature limitation and monitoring in the controller

- Mechanical safety thermostats

- Visual and acoustic fault indications

- Integrated circuit breakers

- Main switch, transformer and motor protection switch

Product informationsTT-390

| Product | TT-390 | ||||

|---|---|---|---|---|---|

| Temperature range | °C | 360 | |||

| Heat transfer medium | oil | ||||

| Filling amount | l | 15 I 21 | |||

| Expansion volume | l | 16 | |||

| Heating capacity | kW | 16 I 24 | |||

| Cooling system | indirect | ||||

| Tubular heat exchanger | kW | 90 | |||

| Plate heat exchanger | kW | ||||

| At flow temperature | °C | 360 | |||

| Pump | |||||

| Motor | kW | 1.8 | |||

| Pump system see diagram | |||||

| Typ Z: axial face sealed 100 l/min; max. 5.5 bar | ⚫ | ||||

| Typ A: magnetic drive 100 l/min; max. 5.5 bar | ◯ | ||||

| Typ X: 260 l/min; max. 4.0 bar | |||||

| Typ Y: 200-500 l/min; max. 4.0 bar | |||||

| Suction capacity vakuum | mWS | 8 | |||

| Controller | MP-888 | ||||

| Measurement sensor | FeKo Typ J | ||||

| Connections | |||||

| Medium | 3/4" BS | ||||

| Cooling water outlet | 1" BS | ||||

| Cooling water inlet | 1" BS | ||||

| Water-glycol | - | ||||

| Compressed air min. | bar | - | |||

| Dimensions incl. castors, LxWxH | mm | 1240x480x1400 | |||

| Weight empty approx. | kg | 205 I 215 | |||

| Colour | silvergrey RAL 7001 | ||||

| Functions | ● standard/ ○ optional / - not possible | ||||

| Flow control | ⚫ | ||||

| Leakstopper device | ⚫ | ||||

| Mould drain | ⚫ | ||||

| Temperature regulation at the consumer | ⚫ | ||||

| Interface controller | ◯ | ||||

| Level control | ⚫ | ||||

| Visual fault indications | ⚫ | ||||

| Acoustic warning | ⚫ | ||||

| Pressure regulation | - | ||||

| Double circuit version | ⚫ | ||||

Imperial

Oil temperature control unit - also available as 2-circuit deviceTT-390

Moulds, rollers, plates

Eckdaten

- Maximum temperature 680°F

- Medium oil

- Heating capacity 54‘594 BTU/hr I 81‘891 BTU/hr

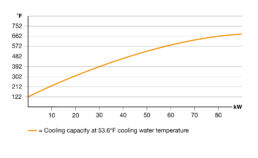

- Cooling capacity 90 kW @ 680°F

- Cooling system indirect

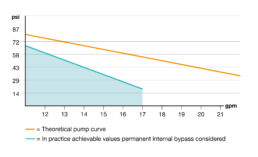

- Pump capacity with axial face seal 26.4 gpm; max. 80 psi

- With magnetic drive 26.4 gpm; max. 80 psi

Functions

- Self-optimizing temperature controller with temperature display

1/10°F – steps - Display in °C or °F and l/min or gal/min

- Digital flow display and monitoring

- Automatic temperature control

- Switchover for temperature control on the mould

- Heating switchable in stages

- Heaters with cascade connection (only 24 kW)

- Pressure display

- Automatic mould drainage

- Leakstopper device – operation in pressure and vacuum mode possible

Construction

- High temperature pump with mechanical seal or magnetic coupling

- Hot oil circuit with bypass, which ensures the internal oil circulation when the valves are closed

- Limescale free heat exchanger

- No cracking of the oil thanks to special heating construction

- Expansion tank with drip pan

- Unit on castors

Safety features

- Level control for dry run protection

- Expansion vessel with safety shut-off in case of overflow

- Electronic temperature limitation and monitoring in the controller

- Mechanical safety thermostats

- Visual and acoustic fault indications

- Integrated circuit breakers

- Main switch, transformer and motor protection switch

Product informationsTT-390

| Product | TT-390 | ||||

|---|---|---|---|---|---|

| Temperature range | °F | 680 | |||

| Heat transfer medium | oil | ||||

| Filling amount | US gal | 4 I 5.5 | |||

| Expansion volume | US gal | 4.2 | |||

| Heating capacity | BTU/hr | 54'594 I 81'891 | |||

| Cooling system | indirect | ||||

| Tubular heat exchanger | kW | 90 | |||

| Plate heat exchanger | kW | ||||

| At flow temperature | °F | 680 | |||

| Pump | |||||

| Motor | HP | 2.4 | |||

| Pump system see diagram | |||||

| Typ Z: axial face sealed 26.4 gpm; max. 80 psi | ⚫ | ||||

| Typ A: magnetic drive 26.4 gpm; max. 80 psi | ◯ | ||||

| Typ X: 69 gpm; max. 58 psi | |||||

| Typ Y: 53-132 gpm; max. 58 psi | |||||

| Suction capacity vakuum | inHg | 23.17 | |||

| Controller | MP-888 | ||||

| Measurement sensor | FeKo Typ J | ||||

| Connections | |||||

| Medium | 3/4" NPT | ||||

| Cooling water outlet | 1" NPT | ||||

| Cooling water inlet | 1" NPT | ||||

| Water-glycol | - | ||||

| Compressed air min. | psi | - | |||

| Dimensions incl. castors, LxWxH | inch | 48.8x18.9x55.1 | |||

| Weight empty approx. | lbs | 452 I 474 | |||

| Colour | silvergrey RAL 7001 | ||||

| Functions | ● standard/ ○ optional / - not possible | ||||

| Flow control | ⚫ | ||||

| Leakstopper device | ⚫ | ||||

| Mould drain | ⚫ | ||||

| Temperature regulation at the consumer | ⚫ | ||||

| Interface controller | ◯ | ||||

| Level control | ⚫ | ||||

| Visual fault indications | ⚫ | ||||

| Acoustic warning | ⚫ | ||||

| Pressure regulation | - | ||||

| Double circuit version | ⚫ | ||||