- |

- Products

- |

- Water Temperature Control Units

- |

- TT-118 K

Metric

Device with two-stage cooling system and large return volumeTT-118 K

Rollers, plates, double-walled vessels, large consumers

Summary

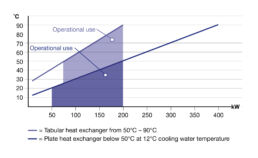

- Maximum temperature 90°C

- Medium water

- Heating capacity: 18 kW I 27 kW l 36 kW l 45 kW

- Cooling capacity

200 kW @ 90°C indirect

400 kW @ 90°C direct - Cooling system indirect

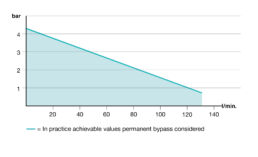

- Pump capacity 200 l/min; max. 4.3 bar

Functions

- Self-optimizing temperature controller with temperature display

1/10°C – steps - Display in °C or °F and l/min or gal/min

- Digital flow display and monitoring

- Automatic temperature control

- Switchover for temperature control on the mould

- Heating switchable in stages

- Heater with cascade connection (only 27 kW / 36 kW / 45 kW)

- Pressure display

- Time limited water refill

- Leakstopper device – operation in pressure and vacuum mode possible

Construction

- Submersible sealless pump made from bronze

- With two cooling systems: tubular and plate heat exchangers

- Limescale free heat exchanger

- Corrosion resistant device for a long service life

- All parts in contact with water are made of stainless steel or bronze

- Unit on castors

Safety features

- Level control for dry run protection

- Electronic temperature limitation and monitoring in the controller

- Mechanical safety thermostats

- Visual and acoustic fault indications

- Integrated circuit breakers

- Main switch, transformer and motor protection switch

Product informationsTT-118 K

| Product | TT-118 K | ||||

|---|---|---|---|---|---|

| Temperature range | °C | 90 | |||

| Heat transfer medium | water | ||||

| Filling amount max. | l | 40 | |||

| Heating capacity | kW | 18 kW I 27 kW I 36 kW I 45 kW | |||

| Cooling system | indirect | ||||

| tubular heat exchanger | kW | 200 | |||

| Plate heat exchanger | kW | 400 | |||

| Direct | kW | ||||

| At flow temperature | °C | 90 | |||

| Pump system see diagram | |||||

| Typ L: 19 l/min; max. 2.9 bar; motor 0.27 kW | |||||

| Typ E: 60 l/min; max. 4.0 bar; motor 0.75 kW | |||||

| Typ H: 60 l/min; max. 7.0 bar; motor 1.50 kW | |||||

| Typ K: 200 l/min; max. 4.3 bar; motor 2.2 kW | ⚫ | ||||

| Typ W: 250-350 l/min; max. 4.5 bar; motor 4.0 kW | |||||

| Typ V: 580 l/min; max. 4.1 bar; motor 7.5 kW | |||||

| Suction capacity vakuum | mWS | 8 | |||

| Controller | MP-888 | ||||

| Measurement type | FeKo Typ J | ||||

| Connections | |||||

| Medium | 1" BS | ||||

| Cooling water | 1" BS | ||||

| Compressed air | - | ||||

| Dimensions incl. castors, LxWxH | mm | 1240x480x1400 | |||

| Weight empty approx. | kg | 180 | |||

| Colour | silbergrau RAL 7001 | ||||

| Functions | ● standard/ ○ optional / - not possible | ||||

| Flow control | ⚫ | ||||

| Leakstopper device | ⚫ | ||||

| Mould drain | - | ||||

| Temperature control at the consumer | ⚫ | ||||

| Time limited water refill | ⚫ | ||||

| Interface controller | ◯ | ||||

| Automatic refill | ⚫ | ||||

| Level control | ⚫ | ||||

| Visual fault indications | ⚫ | ||||

| Acoustic warning | ⚫ | ||||

| Pressure regulation | - | ||||

Imperial

Device with two-stage cooling system and large return volumeTT-118 K

Rollers, plates, double-walled vessels, large consumers

Summary

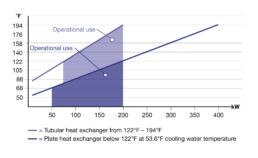

- Maximum temperature 90°C

- Medium water

- Heating capacity: 61‘419 BTU/hr I 92‘128 BTU/hr l 122’837 BTU/hr l 153’546 BTU/hr

- Cooling capacity

200 kW @ 194°F indirect

400 kW @ 194°F direct - Cooling system indirect

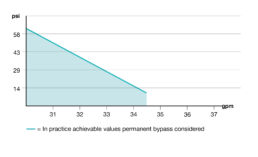

- Pump capacity 53 gpm; max. 62 psi

Functions

- Self-optimizing temperature controller with temperature display

1/10°F – steps - Display in °C or °F and l/min or gal/min

- Digital flow display and monitoring

- Automatic temperature control

- Switchover for temperature control on the mould

- Heating switchable in stages

- Heater with cascade connection (only 27 kW / 36 kW / 45 kW)

- Pressure display

- Time limited water refill

- Leakstopper device – operation in pressure and vacuum mode possible

Construction

- Submersible sealless pump made from bronze

- With two cooling systems: tubular and plate heat exchangers

- Limescale free heat exchanger

- Corrosion resistant device for a long service life

- All parts in contact with water are made of stainless steel or bronze

- Unit on castors

Safety features

- Level control for dry run protection

- Electronic temperature limitation and monitoring in the controller

- Mechanical safety thermostats

- Visual and acoustic fault indications

- Integrated circuit breakers

- Main switch, transformer and motor protection switch

Product informationsTT-118 K

| Product | TT-118 K | ||||

|---|---|---|---|---|---|

| Temperature range | °F | 194 | |||

| Heat transfer medium | water | ||||

| Filling amount max. | gal. | 10.5 | |||

| Heating capacity | BTU/hr | 61'419 BTU/hr I 92'128 BTU/hr I 122'837 BTU/hr I 153'546 BTU/hr | |||

| Cooling system | indirect | ||||

| tubular heat exchanger | kW | 200 | |||

| Plate heat exchanger | kW | 400 | |||

| Direct | kW | ||||

| At flow temperature | °F | 194 | |||

| Pump system see diagram | |||||

| Typ L: 5 gpm; max. 42 psi; motor 0.36 HP | |||||

| Typ E: 16 gpm; max. 58 psi; motor 1 HP | |||||

| Typ H: 16 gpm; max. 102 psi; motor 2 HP | |||||

| Typ K: 53 gpm; max. 62 psi; motor 3 HP | ⚫ | ||||

| Typ W: 66-93 pgm; max. 65 psi; motor 5.4 HP | |||||

| Typ V: 153 gpm; max. 59 psi; motor 10 HP | |||||

| Suction capacity vakuum | inHg | 23.17 | |||

| Controller | MP-888 | ||||

| Measurement type | FeKo Typ J | ||||

| Connections | |||||

| Medium | 1" NPT | ||||

| Cooling water | 1" NPT | ||||

| Compressed air | - | ||||

| Dimensions incl. castors, LxWxH | inch | 48.8×18.9×55.1 inch | |||

| Weight empty approx. | lbs | 397 | |||

| Colour | silbergrau RAL 7001 | ||||

| Functions | ● standard/ ○ optional / - not possible | ||||

| Flow control | ⚫ | ||||

| Leakstopper device | ⚫ | ||||

| Mould drain | - | ||||

| Temperature control at the consumer | ⚫ | ||||

| Time limited water refill | ⚫ | ||||

| Interface controller | ◯ | ||||

| Automatic refill | ⚫ | ||||

| Level control | ⚫ | ||||

| Visual fault indications | ⚫ | ||||

| Acoustic warning | ⚫ | ||||

| Pressure regulation | - | ||||